1. Kodi silinda yowotcherera ndi chiyani?Mtsukowo umawotchedwa mwachindunji kumapeto kwa zipewa ndipo madoko amawotchedwa ku mbiya.Kutsogolo kwa ndodo nthawi zambiri kumakhala bolt kapena kulowetsedwa mu mbiya ya silinda, zomwe zimalola kuti gulu la pisitoni ndi zisindikizo zichotsedwe kuti zigwiritsidwe ntchito.Masilinda a hydraulic welded ali ndi maubwino angapo kuposa masilinda a ndodo zomangira.Ngakhale masilindala omangira ndodo amatha kukhala otsika mtengo kupanga, nthawi zambiri amatengedwa ngati zinthu "zapashelufu" ndipo amakhala ndi zosankha zochepa potengera momwe mungasinthire.Amakhalanso ocheperapo kuposa masilindala owotcherera.Ma cylinders okhala ndi ma welded amatha kupangidwa mwamakonda kuti agwiritse ntchito.Ma cylinders otsekemera amakhalanso ndi mapepala apamwamba osindikizira, omwe angathandize kuonjezera nthawi ya moyo wa silinda ndipo akhoza kukhala opindulitsa pamene silinda idzagwiritsidwa ntchito m'malo omwe amawononga zowonongeka ndi nyengo.Mwachisangalalo, masilinda a thupi owotcherera amakhala ndi mbiri yocheperako kuposa masilinda a ndodo ndipo amatha kusintha mawonekedwe a zida zomwe amagwiritsidwa ntchito.Popeza ndizocheperako kuposa zofananira ndi tayi, masilinda a hydraulic welded amagwira bwino ntchito momwe malo ndi chinthu.

2. Kodi kuwongolera khalidwe kuwotcherera pa kupanga misa?

Zida Zowotcherera;Konzani kuwotcherera chitsanzo mosamalitsa malinga ndi zomwe anakonzeratu ndondomeko zofunika: Preheating, kuwotcherera, kuteteza kutentha, ndi kukonzekera kuwotcherera chitsanzo.Ndi kupanga kuwotcherera ndondomeko khadi kupereka maziko a kukhazikitsa kuwotcherera;Zida zowotcherera, waya wowotcherera ndi mpweya wowotcherera ndi zida zofananira, magwiridwe antchito okhazikika, chiyero chamafuta ambiri, komanso zowerengera zolondola;Wowotcherera, ayenera kukhala ndi satifiketi yowotcherera;Kuyesa kuwotcherera, monga kuyesa mphamvu ya weld bead ndi kuyesa kwa akupanga kuti muwone momwe kuwotcherera.

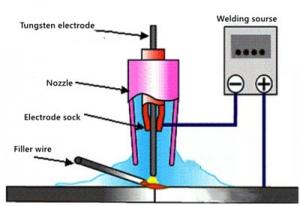

3. Kuwotcherera kwa gasi kungathe kugawidwa mu kuwotcherera kwa inert gasi (TIG kuwotcherera), kuwotcherera kwa gasi wotetezedwa (kuwotcherera kwa MAG).Mwachiwonekere, argon amagwiritsidwa ntchito kwambiri chifukwa cha mtengo wake wotsika mtengo, motero kuwotcherera kwachitsulo kwa inert kumadziwikanso kuti kuwotcherera kwa argon arc.Kuwotcherera kwa mpweya wa Tungsten ndi njira yowotcherera yomwe tungsten kapena aloyi ya tungsten imagwiritsidwa ntchito ngati ma elekitirodi, ndipo arc yomwe imapangidwa pakati pa ma elekitirodi ndi zinthu zoyambira zimagwiritsidwa ntchito kusungunula zinthu zoyambira ndikudzaza waya pansi pachitetezo cha mpweya wa inert. .

TIG, yomwe imadziwikanso kuti Gas Arc Welding (GTAW), ndi njira yopangira Arc pakati pa elekitirodi ya Tungsten ndi chitsulo choyambira pansi pa chitetezo cha mpweya wa inert kuti zitsulo zoyambira ndi waya zowotcherera zisungunuke ndikumangirira.Zimaphatikizapo kuwotcherera kwa DC TIG ndi kuwotcherera kwa AC TIG.

Kuwotcherera kwa DC TIG kumatenga gwero lamagetsi la DC arc ngati gwero lamagetsi, lomwe lili ndi mphamvu zoyipa kwambiri komanso zoyambira zabwino.Amagwiritsidwa ntchito kwambiri pakuwotcherera chitsulo chosapanga dzimbiri, titaniyamu, mkuwa ndi aloyi yamkuwa.Mphamvu yowotcherera ya AC TIG kuwotcherera imachokera ku AC arc, ndipo anode ndi cathode yazinthu zoyambira zidasintha.EP polarity elekitirodi kutenthedwa akhoza kuchotsa m'munsi zinthu pamwamba okusayidi wosanjikiza, makamaka ntchito zotayidwa, magnesium, ndi aloyi kuwotcherera wina.

Pamene TIG (GTAW) kuwotcherera ntchito, chowotcherera akhoza kuwotcherera mfuti mu dzanja limodzi ndi kuwotcherera waya mu dzanja, oyenera ntchito yaing'ono ndi kukonza kuwotcherera Buku.TIG akhoza welded pafupifupi zitsulo mafakitale onse, amapereka mawonekedwe kuwotcherera wabwino, slag zochepa ndi fumbi akhoza ankagwiritsa ntchito mbale woonda ndi wandiweyani zitsulo.

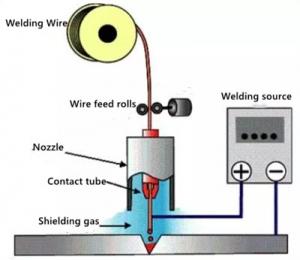

MAG (Metal Active Gas) Welding amagwiritsa ntchito CO₂ kapena kusakaniza kwa argon ndi CO₂ kapena mpweya (Gasi Wogwira Ntchito).Kuwotcherera mpweya wa CO₂ nthawi zina kumatchedwa CO₂ arc kuwotcherera.Zipangizo zowotcherera za MIG ndi MAG ndizofanana chifukwa zimatha kudyedwa kuchokera ku nyali ndi chowotchera waya ndipo ndizoyenera kuwotcherera zokha, osatchulanso kuwotcherera pamanja.Kusiyana kwakukulu pakati pawo kuli mu gasi woteteza, woyambayo nthawi zambiri amatetezedwa ndi mpweya wa argon, oyenera kuwotcherera zitsulo zopanda chitsulo;MAG kuwotcherera makamaka amagwiritsa ntchito mpweya wa CO₂, kapena mpweya wosakanikirana wa argon wa CO₂, womwe ndi Ar+2%O₂ kapena Ar+5%CO₂, yoyenera kuwotcherera chitsulo cholimba kwambiri komanso chitsulo cha alloy.Pofuna kupititsa patsogolo kayendedwe ka CO₂welding, CO₂+Ar kapena CO₂+Ar+O₂ wosakaniza wa gasi kapena waya wa flux-cored angagwiritsidwenso ntchito.Kuwotcherera kwa MAG kumadziwika ndi liwiro lake kuwotcherera mwachangu, kuyendetsa bwino kwa arc, dziwe lakuya, magwiridwe antchito apamwamba, mawonekedwe abwino, osavuta kugwiritsa ntchito, oyenera kuwotcherera kothamanga kwambiri kwa MIG (GMAW).

Fast yadzipereka ku R&D ndikupangama silinda a hydraulicndi ma hydraulic systems, kutumikira makasitomala ndikupatsa antchito moyo wabwino.Mpaka pano, tathandiza masauzande amakasitomala padziko lonse lapansi ukadaulo wopereka ma hydraulic cylinder ndi kapangidwe ka makina okhala ndi mwayi wampikisano.

Nthawi yotumiza: Sep-16-2022